Photovoltaic power bases are increasingly being deployed in regions where environmental conditions are particularly harsh. These areas often experience extreme temperatures, high levels of dust, and rugged terrain, and all of these things pose massive challenges for traditional power systems. Therefore, operating energy solutions in these demanding environments require highly adaptable state-of-the-art equipment. This is where modular inverters act as a game changer.

See the Ground-Breaking Modular Inverter from Sungrow – Coinciding with Locals

Last year, the launch of 1.1MW to 8.8MW modular inverter was brought into the spotlight. This cutting-edge solution is designed to meet the needs of ultra-large PV plants and combines the advantages of both central and string inverters. The modular design is a highly flexible solution that is easy to maintain even for large-scale solar installations.

Here are features of this inverter:

· Scalability and Flexible Design

The 1+X Modular Inverter is designed to scale from 1.1MW to 8.8MW, which provides exceptional flexibility in PV plant design. Each unit operates independently; in other words, if there is something wrong with one module, the rest of the system will not be affected.

· Modular Components for Easy Maintenance

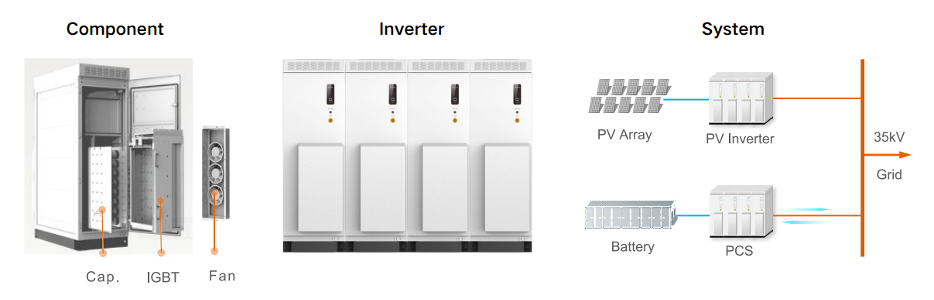

The 1+X Modular Inverter is modularly designed at component, inverter, and system levels, which makes the PV plant design more flexible and the O&M more convenient. Its key components, such as IGBTs, fans, and capacitors, are designed for plug-and-play, which makes the time efficiency of the O&M improve by about 70%. Even non-professionals can easily do repair work.

· Advanced Wireless Communication

The 1+X Modular Inverter includes an optional wireless communication feature that supports up to 50 combiner boxes and can operate over distances up to 1000 meters. The automatic frequency hopping capability ensures the elimination of cross-talk between different blocks, while the mesh networking functionality fosters stable and efficient wireless communication even in adverse communication environments.

· Exceptional Design for Harsh Environments

With an IP65 protection level, the 1+X Modular Inverter is built to operate perfectly, even in harsh environments, such as high interference of dust and sand. Its cabinet design includes separate cavities for heat dissipation and electronic components. It is managed by an intelligent forced air-cooled system and a heat exchanger, which maintains its sustainability of operation.

· Safety Features

The premium safety features of this modular inverter include real-time parallel arc detection, which can identify and respond to arc faults within 20 milliseconds. Furthermore, the 1+X Modular Inverter incorporates synchronized linkage capabilities, enabling it to seamlessly disconnect the remaining SCB switches, thereby mitigating potential further losses. This rapid detection and response mechanism prevents equipment damage, energy loss, and potential injuries.

Everything About Modular Inverters

A modular inverter is an electrical device that incorporates a modular design approach, allowing for greater flexibility, scalability, and ease of maintenance. It represents a significant innovation in inverter technology.

The modular design of the inverter offers more advantages over the standard inverter in reducing downtime and maintenance costs, suiting wide-range applications, and monitoring system performance.

Modular Inverters vs. Standard Inverters – the Strengths of Modular Inverters

| Modular Inverter | Standard (Integrated) Inverter |

Design | Composed of separate, replaceable components (modules). | Parts are interconnected; components are not easily swapped. |

Maintenance & Repair | Easy to maintain and repair by swapping out individual modules without affecting the rest of the system. | More time-consuming to maintain and repair, often requiring full downtime. |

Flexibility | It can be reconfigured to fit spaces with unique dimensions. | Limited flexibility in design and configuration. |

Lifespan | Typically longer due to easier, hassle-free repairs. | It may have a similar manufactured lifespan but is harder to repair and maintain. |

Hot Swapping | Allows hot swapping, enabling component replacement while the inverter is energized, reducing downtime. | Does not support hot swapping; it requires a complete shutdown for repairs. |

Business Continuity | Enhanced by redundancy and hot swapping, avoiding interruptions. | Downtime required during repairs can impact business continuity. |

Usage | Often used for industrial purposes requiring high productivity and minimal downtime. | Typically used in less demanding environments where downtime is acceptable. |

Conclusion

With expertise and rich experience in offering reliable renewable energy solutions, we are among the pioneers in the solar inverter industry. Contact Sungrow to embrace the renewable energy journey.